Innovating Materials, Enriching Lives

Service hotline:13378657020

■ Brief Introduction

In order to improve its compatibility with organic interfaces and reduce or eliminate the embrittlement or performance degradation of organic materials caused by the addition of aluminum hydroxide, surface modification is necessary. The modified aluminum

Before aluminum hydroxide is surface-treated, it has many surface-active hydroxyl groups and certain polarity, making it difficult to disperse during downstream processing and thus affecting performance. To improve its compatibility with organic interfaces and reduce or eliminate the embrittlement or performance degradation of organic materials caused by the addition of aluminum hydroxide, surface modification of aluminum hydroxide is necessary. Modified aluminum hydroxide has a lower oil absorption and significantly improved dispersibility compared to unmodified powder.

■ Product Features

- With low oil absorption value and enhanced hydrophobicity

- Good dispersibility, less prone to agglomeration, and better anti-settling performance

- Modified aluminum hydroxide with increased cross-linking

- The cross section at the junction of groups is blurry, resulting in better dispersion

■ Product technical parameters

Products Name:Modified aluminum hydroxide

| Modification type | Model No. | Whiteness | D50 (μm) | D90 (μm) | Oil absorption value (g/100g) | Moisture (%) |

| Vinyl modification | ATH-1 | ≥97 | ≤1.8 | ≤3.5 | 25-35 | ≤0.50 |

| ATHZ-1 | ≥97 | ≤1.8 | ≤3.5 | 25-35 | ≤0.50 | |

| ATH-5B | ≥93 | 5.0±0.5 | 14.0±1.5 | 20-35 | ≤0.50 | |

| ATH-2 | ≥97 | ≤1.8 | ≤3.5 | 25-35 | ≤0.50 | |

| Isocyanate modification | ATH-6 | ≥91 | ≤13.5 | ≤28.5 | 5-15 | ≤0.50 |

| Stearic acid modification | ATH-3 | ≥97 | ≤1.8 | ≤3.5 | 20-35 | ≤0.50 |

| Epoxy modification | ATH-5A | ≥93 | 5.0±0.5 | 14.0±1.5 | 20-35 | ≤0.50 |

| Composite modification | ATH-1T | ≥97 | ≤1.8 | ≤3.5 | 15-30 | ≤0.50 |

| ATH-1I | ≥97 | ≤1.8 | ≤3.5 | 20-35 | ≤0.50 |

The specific product values are subject to the actual factory inspection report.

■ Application data

| Physical properties | Testing standard | Scheme 1 | Scheme 2 | Scheme 3 | Scheme 4 | Scheme 5 |

| Model No. | / | ATH-1 | ATHZ-1 | Competito 1 | Competito 2 | Competito 3 |

| Hardness A | GB/T531-2008 | 71 | 72 | 69 | 69 | 64 |

| Density g/cm³ | GB/533-2008 | 1.511 | 1.507 | 1.502 | 1.516 | 1.510 |

| Plasticity 0.01mm | IS07323 | 275 | 283 | 278 | 265 | 245 |

| Tensile strength MPa | GB/T528-2009 | 6.77 | 6.13 | 6.10 | 5.41 | 3.51 |

| Elongation at break % | GB/T528-2009 | 174 | 178 | 205 | 212 | 405 |

| Tear strength kN/m | GB/T529-2009 | 9.11 | 8.56 | 9.19 | 9.06 | 10.03 |

The specific product values are subject to the actual factory inspection report.

- In terms of tensile strength: ATH-1 > ATHZ-1 > Competitor 1 > Competitor 2 > Competitor 3. Among the above powders, ATH has the best effect in modification and reinforcement.

- In terms of elongation at break: Competitor 3 > Competitor 2 > Competitor 1 > ATHZ-1 > ATH-1. Among the above powders, Competitor 3 has the best performance in terms of elongation.

- In terms of hardness: ATH-1 > ATHZ-1 > Competitor 1 = Competitor 2 > Competitor 3. Among the above powders, both ATH-1 and ATHZ-1 have higher hardness than the competitor products.

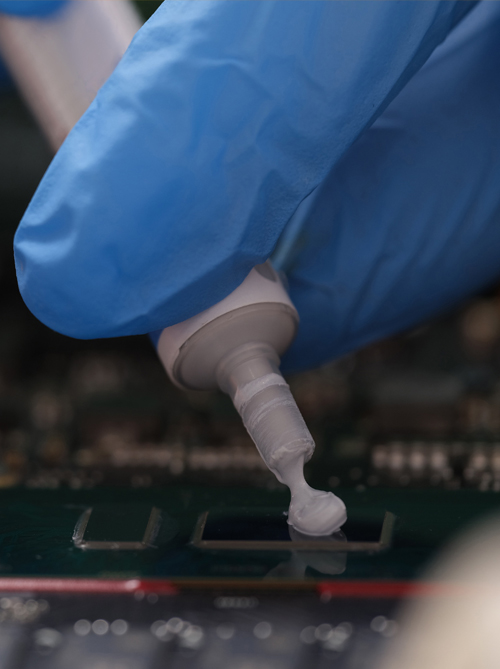

■ Main applications

- Flame-retardant silicone rubber

- Composite insulators

- Wires and cables

- Modified plastics

■ Notes

- For silicone rubber that requires improved aging resistance (no yellowing after thermal aging), please communicate with our sales staff in advance to obtain customized samples (containing phenylsilane and siloxane).

- Before testing the composite modified products, it is necessary to first test and analyze the performance and sample differences between the single-treated products and the original powder, and then determine which composite treatment is applicable.

- We accept relevant customized processing requirements. If you have any needs, please communicate with the business person in charge and R&D engineers.

广东海科新材料科技有限公司 地址:深圳市龙岗区平湖街道华南城发展中心25层 电话:13378657020 网址:en.hicocorp.com

GUANG DONG HICO NEW MATERIAL TECHNOLOGY CO.,LTD

■ Technical documents

-

¥Download for freeDownload after commentDownload after login

- {{attr.name}}:

CN

CN