Innovating Materials, Enriching Lives

Service hotline:13378657020

■ Brief Introduction

The modified silica powder series independently developed by Hico is made through surface treatment and fine processing of natural quartz. Its main component is SiO₂. After surface activation modification, it has good affinity with epoxy resin and organosilicon resin. In systems based on epoxy resin and organosilicon resin, it achieves a high filling effect without affecting performance to the maximum extent.

The surface of modified silica fume is equipped with chemical groups that are compatible with organic systems, which can increase the addition amount of modified silica fume and reduce costs. Meanwhile, it improves the processing technology, enhances the combination with organic systems, and makes the physical and chemical properties more excellent.

■ Product Features

- Surface activation treatment has better interface compatibility and is easier to disperse compared to untreated powder

- Special activation modification process, achieving high filling ratio and controlling viscosity in the field of sealing adhesive

- Can achieve material filling without affecting mechanical properties

- Under the microscopic morphology, the edges and corners of the particles are passivated, making them more regular and having better fluidity than conventional silicon micro powders

■ Product technical parameters

Products Name:Modified silica powder

| Modification type | Model No. | Whiteness | D50 (μm) | D90 (μm) | Oil absorption value (g/100g) | Moisture (%) |

| Vinyl modification | HY-G0-2L | 85±2 | ≤17.0 | ≤43.0 | 12-22 | ≤0.50 |

| HY-GB-3 | 91±2 | 3.0-6.0 | 8.0-12.0 | 30-40 | ≤0.50 | |

| Epoxy based modification | HY-GA-2 | 88±2 | 8.0-12.0 | 21.5-25.5 | 22-35 | ≤0.50 |

| HY-GA-3 | 89±2 | 8.0-12.5 | 20.5-28.5 | 15-28 | ≤0.50 | |

| HY-GB-1 | 91±2 | 3.0-6.0 | 8.0-12.0 | 30-40 | ≤0.50 | |

| Silazane modification | HY-G0-2N | 85±2 | ≤17.0 | ≤43.0 | 15-25 | ≤0.50 |

| HY-GA-3N(Composite) | 90±2 | ≤15.0 | / | 10-18 | ≤0.50 | |

| HY-GB-S | 92±2 | 4.0-6.0 | 8.8-12.0 | 20-35 | ≤0.50 | |

| Alkyl modification | HY-GA-2J | 88±2 | ≤13.5 | ≤28.5 | 5-15 | ≤0.50 |

| Oligomer modification | HY-G0-2A | 85±2 | ≤13.5 | ≤28.5 | 5-15 | ≤0.50 |

| HY-GB-4 | 91±2 | 4.0-6.0 | 8.8-12.0 | 20-35 | ≤0.50 |

The specific product values are subject to the actual factory inspection report.

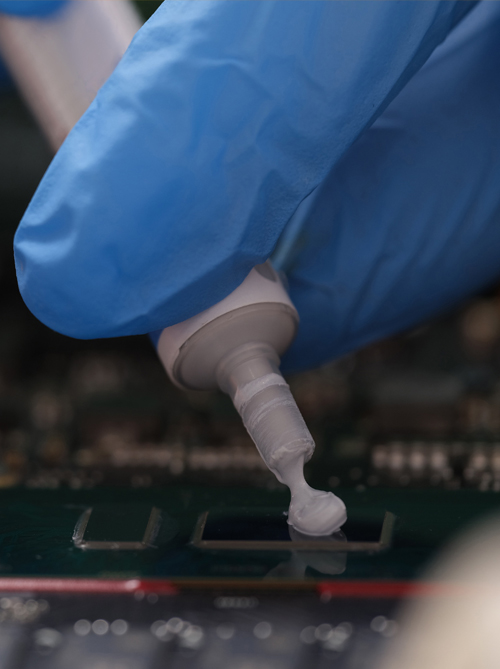

■ Main applications

- Wires and cables

- New energy vehicles

- Energy storage

- Floor coating

- Thermal conductive gasket

- Ink

- Thermal conductive silicone grease

- Thermal conductive potting adhesive

- Thermal conductive gel

■ Notes

- Both the HY-GA series and HY-GB-1 can meet the general requirements. In terms of system pertinence, epoxy is the preferred choice, while the others are all applicable.

- If the potting adhesive product has high requirements for system viscosity and relevant storage stability requirements, further improvement can be made based on the actual test results, using special silane combined with long carbon chain silane for composite modification.

- For polyurethane system requirements, NCO surface customization treatment can be performed, and the dispersion effect is better compared with conventional products.

广东海科新材料科技有限公司 地址:深圳市龙岗区平湖街道华南城发展中心25层 电话:13378657020 网址:en.hicocorp.com

GUANG DONG HICO NEW MATERIAL TECHNOLOGY CO.,LTD

■ Technical documents

-

¥Download for freeDownload after commentDownload after login

- {{attr.name}}:

CN

CN