Innovating Materials, Enriching Lives

Service hotline:13378657020

■ Brief Introduction

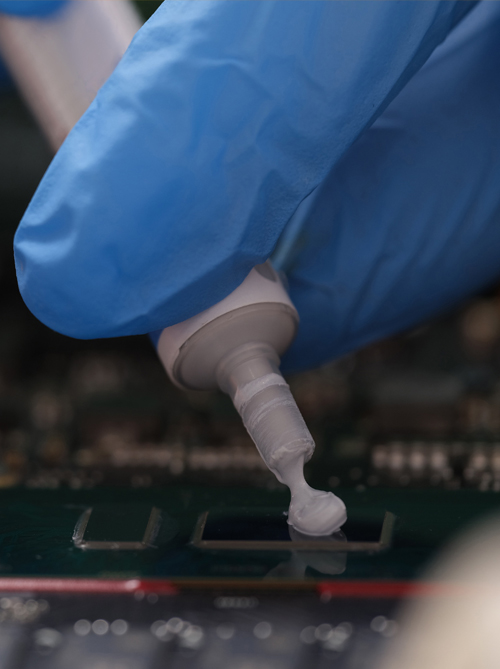

Ceramic composite powder is a ceramic fireproof functional powder obtained by compounding aluminum hydroxide, flame retardant, wollastonite, zirconia, lithium ceramic stone, low melting point glass powder, etc. It can be used in the fields of wire and cable fireproof ceramic silicone rubber/polyolefin, electronic device packaging room temperature curing liquid ceramic adhesive, fireproof ceramic coating, fireproof lightweight foam.

■ Product Features

- 450 degrees Celsius low-temperature porcelain production

- Specific fire resistance

- Good thermal insulation

- Mature application in silicone rubber and polyolefin systems

■ Product technical parameters

Products Name:Ceramic composite powder

| Modification type | Model No. | Exterior | D50 (μm) | D90 (μm) | Oil absorption value (g/100g) | Moisture (%) |

| Composite modification | CFP-3A22 | White | 3.0-5.0 | 16.0-19.0 | 20-28 | ≤0.50 |

| Applicable category | For solid ceramizable silica gel | |||||

| Single modification | CFP-1Z | Grayish white | ≤7.5 | ≤28.0 | 20-28 | ≤0.50 |

| Applicable category | Both solid and liquid forms are applicable, but they need to be used with a flame-retardant system | |||||

The specific product values are subject to the actual factory inspection report.

■ Application data

Solid silicone rubber (recommended dosage: mass fraction 50-60%)

| Performance | Index | Test Method |

| Density (g/cm³) | ≤1.55 | GB/T 1033.1 |

| Tensile Strength (MPa) | ≥3.5 | GB/T 1040.2 |

| Elongation at Break (%) | ≥100 | GB/T 1040.2 |

| Breakdown Voltage (kV/mm) | ≥18 | GB/T 1695 |

| Volume Resistivity (Ω · cm) | ≥10^14 | GB/T1410 |

| Flame Retardancy | FV-0 | GB/T 10707 |

Polyolefin (recommended dosage: mass fraction 60-70%)

| Performance | Index | Test Method |

| Density (g/cm³) | ≤1.55 | GB/T1033.1 |

| Tensile Strength (MPa) | ≥6 | GB/T 1040.2 |

| Elongation at Break (%) | ≥200 | GB/T 1040.2 |

| Breakdown Voltage (kV/mm) | ≥21 | GB/T1695 |

| Volume Resistivity (Ω · cm) | ≥10^14 | GB/T 1410 |

- In terms of tensile strength, the order is: ATH-1 > ATHZ-1 > Competitor 1 > Competitor 2 > Competitor 3. Among the above powders, ATH exhibits the best performance in modification and reinforcement.

- In terms of elongation at break, the order is: Competitor 3 > Competitor 2 > Competitor 1 > ATHZ-1 > ATH-1. Among the above powders, Competitor 3 shows the best performance in terms of elongation.

- In terms of hardness, the order is: ATH-1 > ATHZ-1 > Competitor 1 = Competitor 2 > Competitor 3. Among the above powders, both ATH-1 and ATHZ-1 have higher hardness than the competitor products.

■ Main applications

- Wires and cables

- New energy vehicles

- Energy storage

- Household appliances

■ Notes

- Adjustments can be made based on customers’ product requirements combined with performance feedback after product testing, while balancing the strength before curing, processing performance, and strength after curing.

- The CFP series products currently on display have a porcelain formation temperature range of 450℃~1100℃, and all have undergone porcelain formation tests via muffle furnace baking with heat preservation. If the porcelain formation test is to be conducted via torch burning, it is necessary to communicate with the business personnel in advance to rearrange the samples.

- Currently, both liquid and solid silicone rubber products can meet the performance requirements for porcelain formation.

广东海科新材料科技有限公司 地址:深圳市龙岗区平湖街道华南城发展中心25层 电话:13378657020 网址:en.hicocorp.com

GUANG DONG HICO NEW MATERIAL TECHNOLOGY CO.,LTD

■ Technical documents

-

¥Download for freeDownload after commentDownload after login

- {{attr.name}}:

CN

CN